No matter if the construction is being done for commercial purpose or residential, pavements demands to be strong and sturdy. Durable surface is of obvious requirement here. The necessity of incorporating the high-class raw materials for the same hence gets automatically conveyed. The resilient materials that are used in wider range in this purpose are asphalt premix. Even the contemporary airport runways, racetracks and tennis tracks, etc. are found to be sculpted with it.

A naturally created resource, asphalt, is found to be present hundreds and thousands of years back. However, updated technology in production and construction has enriched its quality and permanence features. Till 1900 the world only received the naturally obtained form of asphalt. By 1907, the construction domain got enticed with the refined form of the same. Increased automobiles and various other facets have forced the pavements and road to be more sturdy and brawny. Hence the importance of Hot Mix Asphalt (HMA) got enhanced. Here is not the end though. So that the mixtures are of first rated quality is an utmost requirement too. This is the reason why, the essential necessity of asphalt premix and pavement test got immaculately increased. That the cement to the sand and various other necessary construction materials are been blended finely with asphalt, is the prior importance of such testing module.

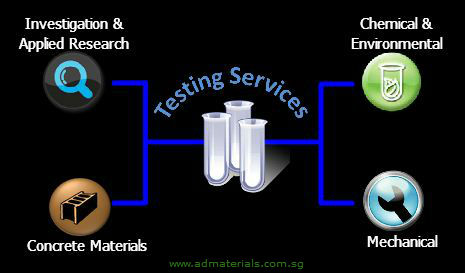

Entities engaged with such analytical testing process, follows an unbiased and impartial work process. Those who are involved with the concrete construction domain get to expand their goodwill with the proper certification by these testing enterprises. That the construction is resistance to any sorts of fatigue or reflective cracking can be assured with such testing regime too. Moisture, low temperature and skids, etc. are some of the other harmful facets related with the concrete built ups. That the materials been used are resistant to all these negativity can also be certified by these testing and certification enterprises. Fair and helpful mode of examination and authentication are best allocated by them.

Majority of these organizations are capable to provide the full range of petrography tests including BS 812 – Pt 104, BS 7943, BS EN 932 – 3, SS EN 12620, ASTM C295 for concrete aggregates. Some of the most competent service providers are even capable to provide ASTM C856 test for hardened concrete and

Majority of these organizations are capable to provide the full range of petrography tests including BS 812 – Pt 104, BS 7943, BS EN 932 – 3, SS EN 12620, ASTM C295 for concrete aggregates. Some of the most competent service providers are even capable to provide ASTM C856 test for hardened concrete and